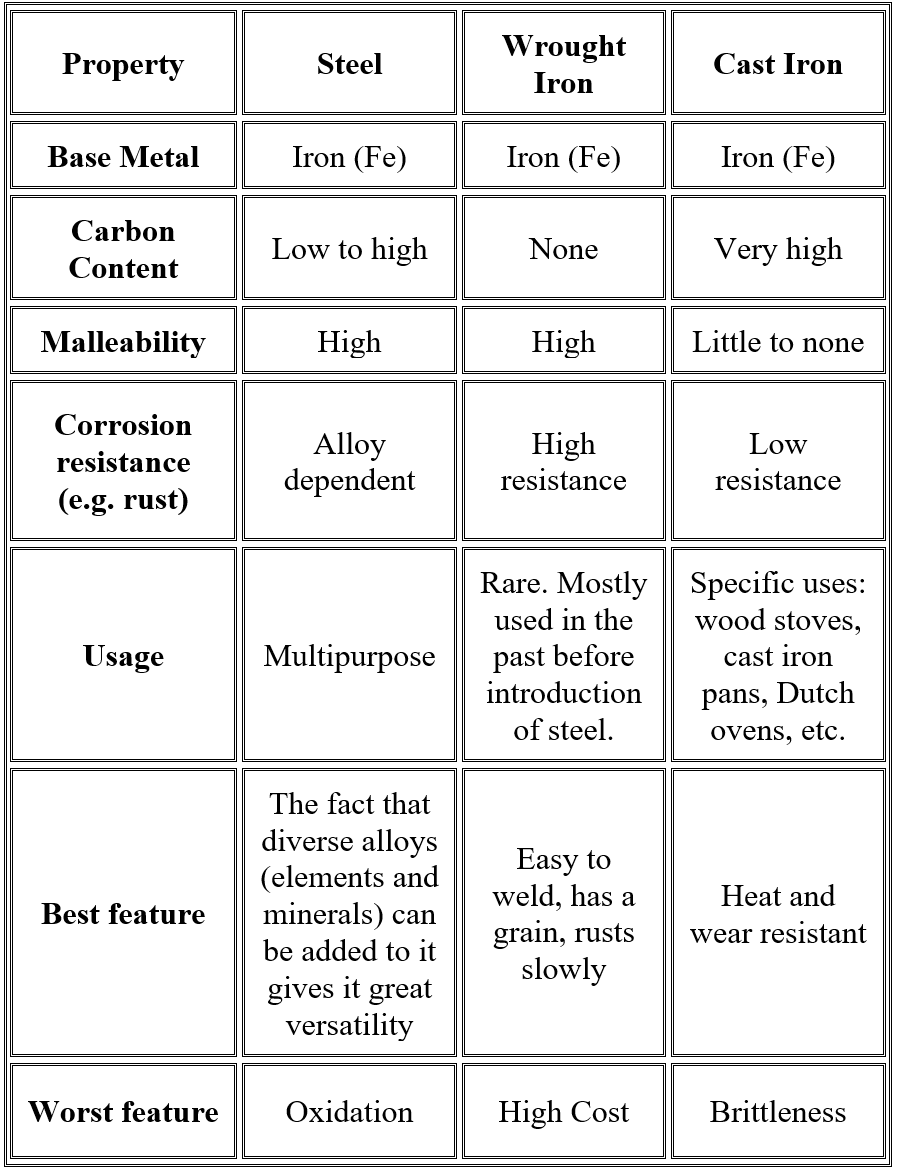

About Metals: Wrought Iron, Cast Iron, and Steel

These three metals are each different and not interchangeable. Wrought iron is actually a type of metal. Today it also, unfortunately, refers to a style of metalwork. Most "wrought iron" today, (fences, railings, fireplace sets, etc.) are made from steel--usually a mild (low carbon) type. Real wrought iron is actually iron, has almost no carbon, and has been “wrought”- worked. It has a grain, like wood, made of silica that runs through the metal. It is 7 times more rust resistant than steel. It’s expensive, in addition to being difficult to find. To that end, most of my work is done with mild steel, though I did bring a cache of wrought iron back from the Iron Bridge Gorge Museum in Birmingham, England.

Cast Iron

Most people are aware that the old wood and coal stoves were made from cast iron. Because the metal has a very open grain it is able to withstand the heat without melting or warping, even though it has a lower melting point than steel. Because cast iron is so hard, it is resistant to wear, however, it is also brittle and susceptible to breakage. It cannot tolerate shock and may crack. Welding cast iron usually requires a pure nickel rod; it cannot be forge-welded.

Cast iron is made in a foundry where the metal is heated to a liquid state and poured into a mold. This differs from the blacksmith's work where the metal is heated to the plastic state, but never melted into a liquid.

Ductile iron is a type of cast iron but far less brittle due to its different grain structure.

Wrought Iron

Almost pure iron, the only other component in wrought iron is the slag imbedded in the iron during processing. As the iron is gathered in the bottom of the smelting furnace, it picks up bits of slag that become long, thin strands as the metal is put though the rolling mill to make bar stock.

As can be seen in the photo of the anchor, wrought iron has grain, like wood. This grain structure must be respected, as any woodworker knows. A metal bar will split on the end just like a board will if you drive a nail too close to the end.

Anchors like the one above still exist today because real wrought iron resists rust 7 times longer than low carbon steel. This is partially due to the silica slag and partially due to the purity of the iron.

Steel

While steel has been in production for a very long time, its use became widespread only after Samuel Bessemer created a way to make large quantities of steel very quickly and cheaply. He first showed his process in 1856, but its use only became widespread as the industrial revolution reached full swing.

There were a few misconceptions to overcome before steel was fully accepted. John Deere made a name by creating the turning plow. It was able to cut through the prairie grass because he had added a cutter wheel and a steel blade. Both modifications reduced the drag of the plow, making it possible for the horses to pull bigger plows. However, acceptance was slow in some areas because the highly polished steel blade was thought to be “bad for the soil.”

A low carbon steel is very malleable, easy to work with and fairly responsive. High carbon steels are much harder and are often used for tools. Steels can be hardened, annealed and tempered.

Harden: heat to bright red (temperature depends on the alloy) and quench (cool quickly)

Anneal: heat to the same temperature and cool slowly, possibly over several days

Temper: done after hardening, by reheating to a lower temperature to remove brittleness and add toughness